Overview of thermal printheads

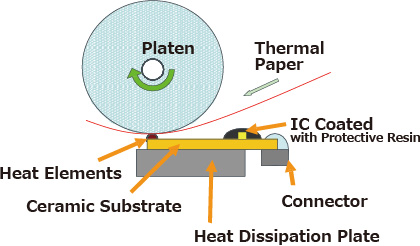

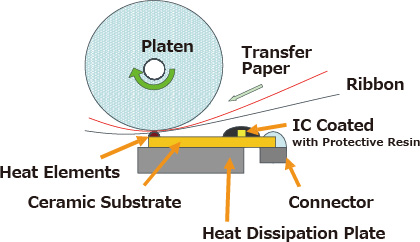

Thermal printheads are devices used to print using thermally sensitive materials (i.e. thermal paper, thermal transfer ribbon) by energizing resistors mounted on a substrate to generate joule heat.

Thermal paper, which is low-cost, easy to handle, and virtually maintenance-free, is used in wide variety of applications, including fax machines, printers, and ticketing equipment.

What's more, improved characteristics such as recording quality and speed have expanded the application range.

Thick-Film and Thin-Film Types (Thermal Printheads)

Thermal printheads are roughly classified into thick-film and thin-film types based on the manufacturing method, materials, and structure.

| Method | Production Process Comparison |

|---|---|

| Thick Film | Film formation by screen printing(Conduction pattern creation via photo-etching) |

| Thin Film | Film formation by sputtering or metal deposition(Conduction pattern creation via photo-etching) |

[Thermal Printhead Manufacturing Method Comparison]

Printing Methods Using Thermal Printheads

Thermal Method

A method of printing achieved by contacting heat elements with thermal paper (special heat-sensitive paper). Frequently used for receipt printers.

| Advantages | ● No need for toner, ribbon, or ink ● Simple printer structure ● Easy to install paper |

|---|---|

| Disadvantages | ● Susceptible to temperature and scratches |

Thermal Transfer Method

A method in which a wax or resin-based ink tape (ribbon) is melted (glued) onto a material such as paper using heat.

| Advantages | ● Excellent water and chemical resistance ● Compatible with plain paper |

|---|---|

| Disadvantages | ● High running costs ● Complicated printer structure ● Difficult to install paper/tape (ribbon) |